Related

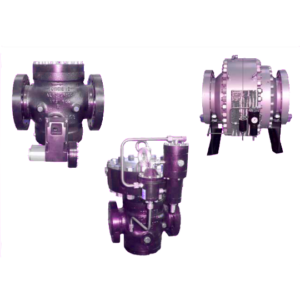

- ON / OFF Axial Flow Valve

- CONTROL Axial Flow Valve

- SURGE RELIEF Axial Flow Valve

- CHOKE Axial Flow Valve

SIZE: 1” ~ 48” (DN25 ~ DN1200)

PRESSURE: 150# ~ 2500# (PN20 ~ PN420)

TEMPERATURE RANGE: -196°C ~ 250°C (538°C)

CONNECTIONS: Wide choice on request

MATERIALS: Wide choice on request

HIGH CAPACITY compared to conventional control valve types

COMPACT and LOW WEIGHT design

STREAMLINED flow path egg shape BODY reducing pressure drop, less velocity and less turbulance, lower noise compared to conventional valves

OPENING AND CLOSING at FULL DIFFERENTIAL PRESSURE

FAST STROKE

PRESSURE BALANCED PISTON enabling fast stroking and low operating torque, leading to a SMALL ACTUATOR requirement

NON-SLAM operation

BI-DIRECTIONAL and BUBBLE TIGHT sealing both upstream or downstream of the valve

FRICTION FREE between sealing areas, no need of partial stroke testing

Full FLOW / PRESSURE / TEMPERATURE CONTROL

VERTICAL or HORIZONTAL orientation possible without modification

RELIABLE DESIGN (often used for HIPPS applications, as Pressure Safety valve or Emergency Shutdown valve)

APPLICATIONS

Oil and gas production

Process industries

Transmission, distribution and storage of fluids

Severe service compressor recycle solution

Used for wide range of fluids:

crude oil to refined products

water and seawater (water injection and deceleration)

natural gas (with contaminants such as sand)

The Valves Corp Axial Flow Valve has the following distinguishing features:

QUARTER TURN STEM DESIGN

Eccentric disk connected to the rotating stem to move the piston rod practically frictionless, compared to a gear-rack which loses more than 50% of its thrust.

Compact actuator due to reduced friction of inside mechanism and balanced piston. Moreover the rotating actuator has a lower stem friction.

High-end stem packing design avoiding fugitive emissions along the stem.

Available in different trim characteristics – cage design (linear, equal percentage, modified stage).

ADVANCED SEALING MECHANISM

Bubble tight shut-off to ANSI class VI, independent of actuation method. Fire safe shut-off to ANSI class V.

Option for dual sealing consisting of two independent mechanisms: a metal-to-metal seal in combination with special design soft seal.

No erosion impact on the seals and noise reduction. Soft seals not in contact with high flow due to special design concentric cage.

FIRE SAFE Fire safe according to API 6FA. Internal leakage is avoided by metal-to-metal seal, whereas external leakage is contained by the graphite containing stuffing box on the rotating stem.

SPLIT BODY DESIGN ALLOWING SHORT LEAD TIMES

Optional cladding

SPECIAL TRIM FOR ANTI-SURGE APPLICATIONS

Special design piston with no erosion during full throttling process fluid inside the sealing area

Reduced stroking time during overshoot set point input

SERIES

Valves Corp ON / OFF Axial Flow Valve

Valves CorpCONTROL Axial Flow Valve

Valves Corp SURGE RELIEF Axial Flow Valve

Valves Corp CHOKE Axial Flow Valve

Valves Corp HIPPS Axial Flow Valve

TRIMS AXF-FS – Fast Shut-off concentric Trim

AXF-CL – Single cage concentric linear Trim

AXF-CEQ – Single cage concentric eq% Trim

AXF-CCL-II – Double cage concentric linear Trim

AXF-CCEQ-II – Double cage concentric eq% Trim

AXF-CCW – Labyrinth cage concentric whisper Trim

|

Design |

API 6D, ASME B16.34 |

|

Face to Face dimensions |

API 6D, ASME B16.10, B16.47 |

|

Flanges |

ASME B16.5, B16.25, BW, Grayloc hubs, API605 (B16.47) |

|

Fire Safe |

ISO 10497, API 6FA, BS 6755 |

|

Fugitive Emission |

ISO 15848, TÜV, Shell MESC SPE 77-312 |

|

Testing |

ANSI/FCI 70.2, API598 |

|

Marking |

CE, MSS-SP-25 |

|

Topworks |

ISO 5211 |

|

Size selection |

ANSI/ISA S75.01-2007 & IEC 60534-8-3:2010 |

|

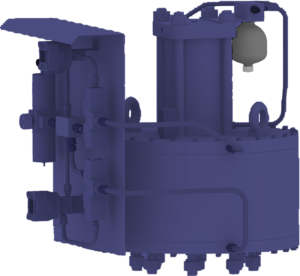

1. Fully Open position Axial Flow Valve is fully open, allowing full flow through the streamlined flow path egg shape body. |

|

|

2. Controlling the flow Rotational movement of the vertical stem (dark yellow circle) is transfered to the horizontal movement of the stem and piston (yellow) by patented mechanism. The piston travels through the cage (red) and closes the holes in the cage based on its position. Holes are distributed in the cage based on desired control characteristics. |

|

|

3. Fully Closed position On 90 degrees turn of the vertical stem, the valve reaches its fully closed position. |

SIZE: 1” ~ 48” (DN25 ~ DN1200)

PRESSURE: 150# ~ 2500# (PN20 ~ PN420)

TEMPERATURE RANGE: -196°C ~ 250°C (538°C)

CONNECTIONS: Wide choice on request

MATERIALS: Wide choice on request

HIGH CAPACITY compared to conventional control valve types

COMPACT and LOW WEIGHT design

STREAMLINED flow path egg shape BODY reducing pressure drop, less velocity and less turbulance, lower noise compared to conventional valves

OPENING AND CLOSING at FULL DIFFERENTIAL PRESSURE

FAST STROKE

PRESSURE BALANCED PISTON enabling fast stroking and low operating torque, leading to a SMALL ACTUATOR requirement

NON-SLAM operation

BI-DIRECTIONAL and BUBBLE TIGHT sealing both upstream or downstream of the valve

FRICTION FREE between sealing areas, no need of partial stroke testing

Full FLOW / PRESSURE / TEMPERATURE CONTROL

VERTICAL or HORIZONTAL orientation possible without modification

RELIABLE DESIGN (often used for HIPPS applications, as Pressure Safety valve or Emergency Shutdown valve)

APPLICATIONS

Oil and gas production

Process industries

Transmission, distribution and storage of fluids

Severe service compressor recycle solution

Used for wide range of fluids:

crude oil to refined products

water and seawater (water injection and deceleration)

natural gas (with contaminants such as sand)

The Valves Corp Axial Flow Valve has the following distinguishing features:

QUARTER TURN STEM DESIGN

Eccentric disk connected to the rotating stem to move the piston rod practically frictionless, compared to a gear-rack which loses more than 50% of its thrust.

Compact actuator due to reduced friction of inside mechanism and balanced piston. Moreover the rotating actuator has a lower stem friction.

High-end stem packing design avoiding fugitive emissions along the stem.

Available in different trim characteristics – cage design (linear, equal percentage, modified stage).

ADVANCED SEALING MECHANISM

Bubble tight shut-off to ANSI class VI, independent of actuation method. Fire safe shut-off to ANSI class V.

Option for dual sealing consisting of two independent mechanisms: a metal-to-metal seal in combination with special design soft seal.

No erosion impact on the seals and noise reduction. Soft seals not in contact with high flow due to special design concentric cage.

FIRE SAFE Fire safe according to API 6FA. Internal leakage is avoided by metal-to-metal seal, whereas external leakage is contained by the graphite containing stuffing box on the rotating stem.

SPLIT BODY DESIGN ALLOWING SHORT LEAD TIMES

Optional cladding

SPECIAL TRIM FOR ANTI-SURGE APPLICATIONS

Special design piston with no erosion during full throttling process fluid inside the sealing area

Reduced stroking time during overshoot set point input

SERIES

Valves Corp ON / OFF Axial Flow Valve

Valves CorpCONTROL Axial Flow Valve

Valves Corp SURGE RELIEF Axial Flow Valve

Valves Corp CHOKE Axial Flow Valve

Valves Corp HIPPS Axial Flow Valve

TRIMS AXF-FS – Fast Shut-off concentric Trim

AXF-CL – Single cage concentric linear Trim

AXF-CEQ – Single cage concentric eq% Trim

AXF-CCL-II – Double cage concentric linear Trim

AXF-CCEQ-II – Double cage concentric eq% Trim

AXF-CCW – Labyrinth cage concentric whisper Trim

|

Design |

API 6D, ASME B16.34 |

|

Face to Face dimensions |

API 6D, ASME B16.10, B16.47 |

|

Flanges |

ASME B16.5, B16.25, BW, Grayloc hubs, API605 (B16.47) |

|

Fire Safe |

ISO 10497, API 6FA, BS 6755 |

|

Fugitive Emission |

ISO 15848, TÜV, Shell MESC SPE 77-312 |

|

Testing |

ANSI/FCI 70.2, API598 |

|

Marking |

CE, MSS-SP-25 |

|

Topworks |

ISO 5211 |

|

Size selection |

ANSI/ISA S75.01-2007 & IEC 60534-8-3:2010 |

|

1. Fully Open position Axial Flow Valve is fully open, allowing full flow through the streamlined flow path egg shape body. |

|

|

2. Controlling the flow Rotational movement of the vertical stem (dark yellow circle) is transfered to the horizontal movement of the stem and piston (yellow) by patented mechanism. The piston travels through the cage (red) and closes the holes in the cage based on its position. Holes are distributed in the cage based on desired control characteristics. |

|

|

3. Fully Closed position On 90 degrees turn of the vertical stem, the valve reaches its fully closed position. |

SIZE: 1” ~ 24” (DN25 ~ DN600)

PRESSURE: 150# ~ 2500# (PN20 ~ PN420)

TEMPERATURE RANGE: -196°C ~ 250°C (538°C)

CONNECTIONS: Wide choice on request

MATERIALS: Wide choice on request

HIGH CAPACITY compared to conventional control valve types

COMPACT and LOW WEIGHT design

STREAMLINED flow path egg shape BODY reducing pressure drop, less velocity and less turbulance, lower noise compared to conventional valves

OPENING AND CLOSING at FULL DIFFERENTIAL PRESSURE

FAST STROKE

PRESSURE BALANCED PISTON enabling fast stroking and low operating torque, leading to a SMALL ACTUATOR requirement

NON-SLAM operation

BI-DIRECTIONAL and BUBBLE TIGHT sealing both upstream or downstream of the valve

FRICTION FREE between sealing areas, no need of partial stroke testing

Full FLOW / PRESSURE / TEMPERATURE CONTROL

VERTICAL or HORIZONTAL orientation possible without modification

RELIABLE DESIGN (often used for HIPPS applications, as Pressure Safety valve or Emergency Shutdown valve)

APPLICATIONS

Oil and gas production

Process industries

Transmission, distribution and storage of fluids

Severe service compressor recycle solution

Used for wide range of fluids:

crude oil to refined products

water and seawater (water injection and deceleration)

natural gas (with contaminants such as sand)

The Valves Corp Axial Flow Valve has the following distinguishing features:

QUARTER TURN STEM DESIGN

Eccentric disk connected to the rotating stem to move the piston rod practically frictionless, compared to a gear-rack which loses more than 50% of its thrust.

Compact actuator due to reduced friction of inside mechanism and balanced piston. Moreover the rotating actuator has a lower stem friction.

High-end stem packing design avoiding fugitive emissions along the stem.

Available in different trim characteristics – cage design (linear, equal percentage, modified stage).

ADVANCED SEALING MECHANISM

Bubble tight shut-off to ANSI class VI, independent of actuation method. Fire safe shut-off to ANSI class V.

Option for dual sealing consisting of two independent mechanisms: a metal-to-metal seal in combination with special design soft seal.

No erosion impact on the seals and noise reduction. Soft seals not in contact with high flow due to special design concentric cage.

FIRE SAFE Fire safe according to API 6FA. Internal leakage is avoided by metal-to-metal seal, whereas external leakage is contained by the graphite containing stuffing box on the rotating stem.

SPLIT BODY DESIGN ALLOWING SHORT LEAD TIMES

Optional cladding

SPECIAL TRIM FOR ANTI-SURGE APPLICATIONS

Special design piston with no erosion during full throttling process fluid inside the sealing area

Reduced stroking time during overshoot set point input

SERIES

Valves Corp ON / OFF Axial Flow Valve

Valves CorpCONTROL Axial Flow Valve

Valves Corp SURGE RELIEF Axial Flow Valve

Valves Corp CHOKE Axial Flow Valve

Valves Corp HIPPS Axial Flow Valve

TRIMS AXF-FS – Fast Shut-off concentric Trim

AXF-CL – Single cage concentric linear Trim

AXF-CEQ – Single cage concentric eq% Trim

AXF-CCL-II – Double cage concentric linear Trim

AXF-CCEQ-II – Double cage concentric eq% Trim

AXF-CCW – Labyrinth cage concentric whisper Trim

|

Design |

API 6D, ASME B16.34 |

|

Face to Face dimensions |

API 6D, ASME B16.10, B16.47 |

|

Flanges |

ASME B16.5, B16.25, BW, Grayloc hubs, API605 (B16.47) |

|

Fire Safe |

ISO 10497, API 6FA, BS 6755 |

|

Fugitive Emission |

ISO 15848, TÜV, Shell MESC SPE 77-312 |

|

Testing |

ANSI/FCI 70.2, API598 |

|

Marking |

CE, MSS-SP-25 |

|

Topworks |

ISO 5211 |

|

Size selection |

ANSI/ISA S75.01-2007 & IEC 60534-8-3:2010 |

|

1. Fully Open position Axial Flow Valve is fully open, allowing full flow through the streamlined flow path egg shape body. |

|

|

2. Controlling the flow Rotational movement of the vertical stem (dark yellow circle) is transfered to the horizontal movement of the stem and piston (yellow) by patented mechanism. The piston travels through the cage (red) and closes the holes in the cage based on its position. Holes are distributed in the cage based on desired control characteristics. |

|

|

3. Fully Closed position On 90 degrees turn of the vertical stem, the valve reaches its fully closed position. |

SIZE: 1” ~ 24” (DN25 ~ DN600)

PRESSURE: 150# ~ 2500# (PN20 ~ PN420)

TEMPERATURE RANGE: -196°C ~ 250°C (538°C)

CONNECTIONS: Wide choice on request

MATERIALS: Wide choice on request

HIGH CAPACITY compared to conventional control valve types

COMPACT and LOW WEIGHT design

STREAMLINED flow path egg shape BODY reducing pressure drop, less velocity and less turbulance, lower noise compared to conventional valves

OPENING AND CLOSING at FULL DIFFERENTIAL PRESSURE

FAST STROKE

PRESSURE BALANCED PISTON enabling fast stroking and low operating torque, leading to a SMALL ACTUATOR requirement

NON-SLAM operation

BI-DIRECTIONAL and BUBBLE TIGHT sealing both upstream or downstream of the valve

FRICTION FREE between sealing areas, no need of partial stroke testing

Full FLOW / PRESSURE / TEMPERATURE CONTROL

VERTICAL or HORIZONTAL orientation possible without modification

RELIABLE DESIGN (often used for HIPPS applications, as Pressure Safety valve or Emergency Shutdown valve)

APPLICATIONS

Oil and gas production

Process industries

Transmission, distribution and storage of fluids

Severe service compressor recycle solution

Used for wide range of fluids:

crude oil to refined products

water and seawater (water injection and deceleration)

natural gas (with contaminants such as sand)

The Valves Corp Axial Flow Valve has the following distinguishing features:

QUARTER TURN STEM DESIGN

Eccentric disk connected to the rotating stem to move the piston rod practically frictionless, compared to a gear-rack which loses more than 50% of its thrust.

Compact actuator due to reduced friction of inside mechanism and balanced piston. Moreover the rotating actuator has a lower stem friction.

High-end stem packing design avoiding fugitive emissions along the stem.

Available in different trim characteristics – cage design (linear, equal percentage, modified stage).

ADVANCED SEALING MECHANISM

Bubble tight shut-off to ANSI class VI, independent of actuation method. Fire safe shut-off to ANSI class V.

Option for dual sealing consisting of two independent mechanisms: a metal-to-metal seal in combination with special design soft seal.

No erosion impact on the seals and noise reduction. Soft seals not in contact with high flow due to special design concentric cage.

FIRE SAFE Fire safe according to API 6FA. Internal leakage is avoided by metal-to-metal seal, whereas external leakage is contained by the graphite containing stuffing box on the rotating stem.

SPLIT BODY DESIGN ALLOWING SHORT LEAD TIMES

Optional cladding

SPECIAL TRIM FOR ANTI-SURGE APPLICATIONS

Special design piston with no erosion during full throttling process fluid inside the sealing area

Reduced stroking time during overshoot set point input

SERIES

Valves Corp ON / OFF Axial Flow Valve

Valves CorpCONTROL Axial Flow Valve

Valves Corp SURGE RELIEF Axial Flow Valve

Valves Corp CHOKE Axial Flow Valve

Valves Corp HIPPS Axial Flow Valve

TRIMS AXF-FS – Fast Shut-off concentric Trim

AXF-CL – Single cage concentric linear Trim

AXF-CEQ – Single cage concentric eq% Trim

AXF-CCL-II – Double cage concentric linear Trim

AXF-CCEQ-II – Double cage concentric eq% Trim

AXF-CCW – Labyrinth cage concentric whisper Trim

|

Design |

API 6D, ASME B16.34 |

|

Face to Face dimensions |

API 6D, ASME B16.10, B16.47 |

|

Flanges |

ASME B16.5, B16.25, BW, Grayloc hubs, API605 (B16.47) |

|

Fire Safe |

ISO 10497, API 6FA, BS 6755 |

|

Fugitive Emission |

ISO 15848, TÜV, Shell MESC SPE 77-312 |

|

Testing |

ANSI/FCI 70.2, API598 |

|

Marking |

CE, MSS-SP-25 |

|

Topworks |

ISO 5211 |

|

Size selection |

ANSI/ISA S75.01-2007 & IEC 60534-8-3:2010 |

|

1. Fully Open position Axial Flow Valve is fully open, allowing full flow through the streamlined flow path egg shape body. |

|

|

2. Controlling the flow Rotational movement of the vertical stem (dark yellow circle) is transfered to the horizontal movement of the stem and piston (yellow) by patented mechanism. The piston travels through the cage (red) and closes the holes in the cage based on its position. Holes are distributed in the cage based on desired control characteristics. |

|

|

3. Fully Closed position On 90 degrees turn of the vertical stem, the valve reaches its fully closed position. |

-

- Select options This product has multiple variants. The options may be chosen on the product page